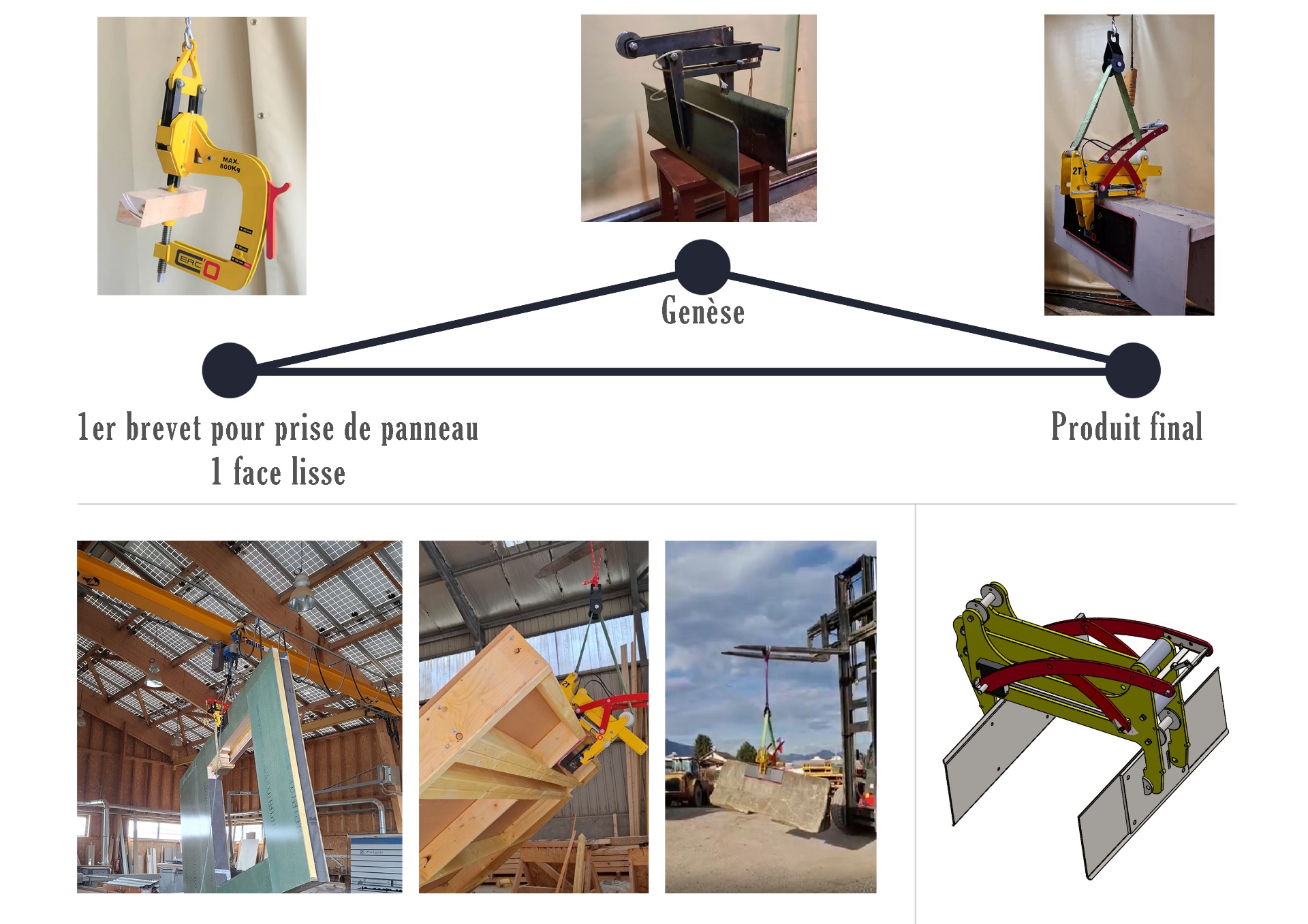

PLIERS FOR GRIPPING TWO SMOOTH SURFACES

The Cerco-L clamp replaces the Cerco-V clamp. Thanks to its lateral gripping system, it is capable of clamping all types of loads.

The ingenious idea behind the Cerco clamp: applying the principle of gravity-driven self-locking. Cerco uses the weight of the load to hold it securely in the clamp's jaws. And the heavier the load being handled, the stronger the clamping force.

The clamping pressure is therefore directly proportional to the weight of the load. And as long as the load is suspended from the end of the clamp, opening is impossible. The operator can only release the clamp once the load is resting on the ground or on a load-bearing surface.

Pince CERCO L

This innovative horizontal-clamping gripper is based on a self-clamping technology that tightens directly onto the load. It is particularly suitable for handling wooden panels or timber-frame walls with two smooth faces, also known as closed-structure walls. It can also be used with any other material, as long as the jaws are in contact with the load to be lifted.

In the video above, you can discover the lateral self-clamping gripping technique, which ensures reliable clamping thanks to generously sized jaws. The lifting capacity can be defined according to your storage or handling needs, ranging from 1 to 3 tonnes, and on request, 4 tonnes, 5 tonnes, 6 tonnes, up to 10 tonnes. Regarding load width capacity (the width of the bundle to be handled), available sizes include 230 mm, 330 mm, 530 mm, and 830 mm, with any other dimensions available upon request. Note that the jaws are coated to avoid marking the panels, and they are interchangeable and available in various sizes to adapt to the type of load.

This clamp can grip a wall horizontally and set it upright vertically, and the opposite is also possible: moving from a vertical to a horizontal position. To achieve this, a brake has been integrated to hold the load securely. Once the load is lifted — and therefore fully clamped — the brake takes over the clamping force generated by the maximum load. This allows you to safely place your load vertically and then rotate it into a horizontal position.

The operator controls the clamp from the ground: opening the clamp, locking it, lifting the load, and unlocking it are all performed from the ground using the ropes attached to the system. The load can then be picked up again if it has been placed on a truck during on-site operations, and positioned precisely after locating its center of gravity. Since the clamp is mobile, it can be moved very easily, allowing the operator to remain safe at all times. This eliminates the need to climb onto the loads or to cut ropes, straps, or other securing systems.

TIME SAVER

Significant time savings during handling and faster maneuvers, therefore increased productivity.

SAFETY FOR ALL

No more need for a ladder to unhook or cut the straps or slings attached to the panel.

PRESERVATION OF INTEGRITY

Preserving the integrity of the handled structure: no more machining or drilling to fix slings in the panels.

EASE OF USE

This provides ease of use for the handler, who can thus remain focused on their handling operation.

BALANCING THE BURDEN

Ease of achieving good load balancing (tightening at the center of gravity of the structure).

UNBALANCE

Elimination of imbalance during transfer operations: workshop/truck then truck/construction site.